Australia’s Pumped Hydro: The Projects, People, and Potential

- Tahnia Miller

- 6 days ago

- 6 min read

We’ve collected insights from interviewing some of the most experienced leaders in the Australian pumped hydro sector. Our experts span the full project lifecycle, from project development, funding and planning through to design, pre-contracts and delivery.

As Australia accelerates its transition from coal to renewables, long-duration energy storage is emerging not just as a challenge, but one of the biggest opportunities in the energy system.

While grid-scale batteries are scaling rapidly, pumped hydro offers something uniquely valuable: low resource use due to long life, high local content, deep storage, grid strength and reliability. It’s no surprise governments, investors, and developers are once again turning to this proven technology to firm the nation’s clean energy future.

Why Pumped Hydro Matters Now

Australia currently has over 5 GW of dispatchable storage in service or commissioning, with 1.7 GW being pumped storage, but AEMO forecasts more than 20 GW will be needed by 2030 to manage variability and coal closures.

For Geoff Scott, Executive General Manager of Delivery at Queensland Hydro, the long-term value of pumped hydro is what truly sets it apart.

“In the right conditions, you’ll have an asset for 150 years. You’ll need to replace the turbines every 40 to 50 years, but pumped hydro offers a long-term solution that very few other power sources can match.”

Geoff Scott often compares pumped hydro to other forms of generation and storage, noting that few assets can deliver both energy and system strength across multiple generations.

Chris Evans, Executive General Manager of Development at Queensland Hydro, adds that pumped hydro's contribution goes well beyond storing electricity:

“Pumped hydro projects deliver system strength, inertia, voltage control and functions essential to a stable and reliable electricity system. But not all of this value is monetised under current market conditions, which is why government support is required to support management of the commerciality gap.”

A Growing Pipeline Across the Country

Australia has only a handful of operating schemes, but a new wave of development is underway.

Kidston Pumped Hydro (QLD)

Kidston is one of the world’s most innovative pumped hydro projects: a 250 MW asset built using two abandoned gold mine pits. Its first generating unit has now been registered with the market, one of the clearest signs the project is nearing completion.

Snowy 2.0 (NSW)

At 2,200 MW and 350,000 MWh of storage, Snowy 2.0 is one of the largest pumped hydro schemes ever constructed. With 27 km of tunnels, underground caverns and globally manufactured turbines, it highlights the scale and complexity of modern PHES.

Borumba (QLD)

The Borumba project is being developed as a large-scale, long-duration pumped hydro scheme in Queensland’s south-east. It is intended to play a major role in firming renewable generation and supporting the future stability of the state’s electricity network.

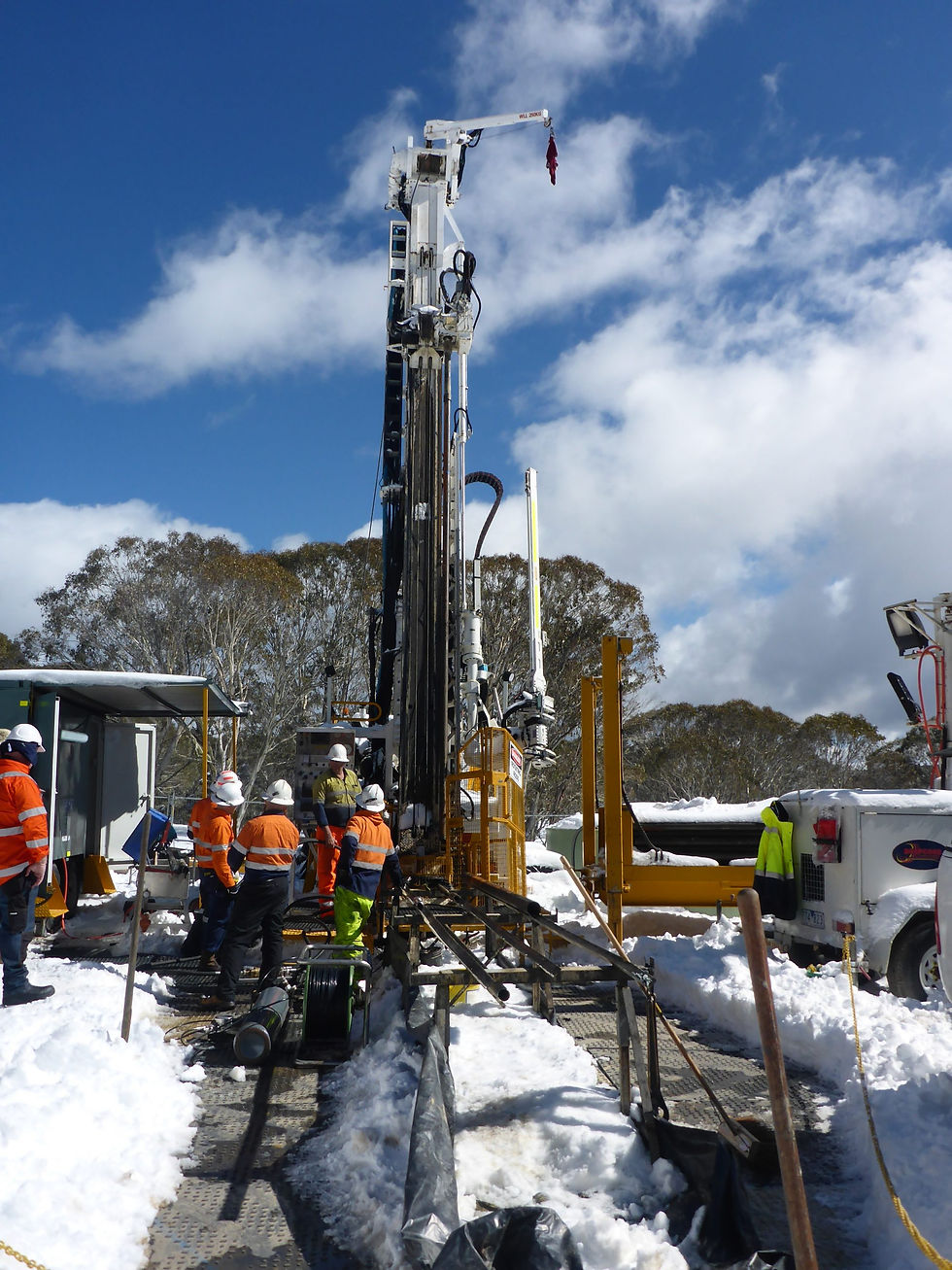

Mount Rawdon: A New Benchmark for Mine-to-Hydro Conversion

Queensland’s Mount Rawdon Pumped Hydro Project is shaping up as one of the most significant PHES developments in Australia: a 1,360 MW, 28 GWh scheme that repurposes an existing gold mine as the lower reservoir.

Marco Stacke, Senior Project Development Manager at CleanCo, says:

“Mount Rawdon will be a global benchmark for sustainable resource transition. Using the former open-pit gold mine sets a new standard for repurposing disturbed mining areas.”

He notes its dual value: mine rehabilitation and major long-duration storage.

“With it’s 20 hours of storage at peak load Mount Rawdon will help stabilise the grid, reduce price volatility and has the potential to reduce system costs by almost $10 billion+ over its life whilst creating over 1000 jobs during construction phase.”

Lessons the Industry Is Learning

Insights from project leaders, engineers and contractors point to five major themes shaping the future of pumped hydro delivery in Australia.

1. Workforce & Capability Gaps Are Significant

Pumped hydro sits at the intersection of civil engineering, tunnelling, hydro-mechanical systems, high-voltage integration, mining logistics, hydrology and complex sequencing.

Marco Stacke notes:

“Deep underground works, vertical shafts, hydro-mechanical integration — there are only a handful of people in Australia with experience in these areas.”

Harry Hartman, Director at Constructionarium Australia, sees this gap daily:

“The workforce gap is everywhere — across all levels and disciplines. These are remote projects with tunnelling and specialised mechanical and electrical scopes.”

Constructionarium has built two scaled pumped-hydro training facilities (Brisbane and Melbourne), enabling emerging engineers to build and commission a functioning 12-metre water battery.

Chris Evans underscores that PHES requires a fundamentally different workforce profile:

“A large pumped hydro project can have a peak workforce upwards of 2,000 people on site during a 5–8 year construction period. Queensland is simultaneously delivering Olympics infrastructure, housing, transport and energy projects — the workforce challenge is enormous.”

2. Commercial Structures and Risk Sharing Matter

Gary Parkinson, IPDM director and experienced hydro delivery leader, emphasises that many pumped hydro projects fail early because of unrealistic risk allocation.

“Clients often start with one-sided risk expectations. Full-wrap EPCs are rarely viable. A balanced risk allocation matrix is essential.”

He and Geoff Scott both support Early Contractor Involvement (ECI) and open-book contracting.

Mike Westerman, who leads the Global Hydropower practice within GHD and has 45 years’ experience in the energy sector, is even more direct:

“A better outcome arises from open-book negotiations based on price and risk. Competitive tendering often sets up an adversarial relationship before the project even begins.”

At Snowy, a soft zone encountered just 50 metres into tunnelling set the project back by 12 months, a stark reminder that even extensive investigation cannot eliminate all risk in underground megaprojects.

Geoff Scott adds, “You can pre-drill all you want, but you’ll never know exactly what you’re going to hit underground.”

3. Early Geotechnical & Scope Definition Are Non-Negotiable

Both Gary Parkinson and Mike Westerman stress the importance of early geotechnical baselines.

Gary Parkinson explains:

“You need early Geotech, but not too early as to not be able to capture any scope/location changes that might occur during an ECI Phase. Adopting Geotechnical Baseline Report (GBR) methodology can also allow the client and contractor to assess possible ground risks and share fairly.”

Mike Westerman reinforces the uncertainty that still exists even with data:

“Data is king. Hard rock mine sites are more anomalous — the geology inside a pit tells you nothing about what lies elsewhere on the alignment.”

Geoff Scott is clear on where responsibility should sit:

“Stop pushing all the geotechnical risk to contractors. Unknown ground conditions are a client risk.”

Chris Evans, drawing on two decades of hydro development, broadens the risk lens:

“There are no easy sites. Technical challenges can typically be managed with engineering and cost, but social and environmental challenges can be fatal if not handled carefully.”

4. Logistics Drive Schedule — Not Engineering Drawings

On Snowy 2.0 alone, there were 13 underground work fronts operating at once.

“Underground sites are logistical nightmares. Humans can’t optimise something that complex — you need software and AI.”

Geoff Scott advocates:

mining methods for excavation

civil methods for installation

digital tools for sequencing and optimisation

5. Pumped Hydro and Batteries Are Partners — Not Competitors

Chris Evans addresses a common misconception:

“Batteries respond extremely fast and handle short-term variations. Pumped hydro comes into its own when demand peaks, after batteries discharge and before solar generation ramps up. And we need both.”

His comparison highlights PHES scale:

A 1,000 MW / 24-hour PHES = 24,000 MWh

A 200 MW / 4-hour battery = 800 MWh

Matching the PHES scheme would require 30 equivalent batteries, replaced five times over its life.

The Future of Pumped Hydro in Australia

If projects like Kidston, Borumba and Mount Rawdon progress as planned, Australia could build one of the world’s most modern long-duration storage fleets.

For Geoff Scott, collaboration will be critical:

“If you treat these as traditional construction projects, you’ll struggle. They need mining-style thinking, early collaboration and realistic risk sharing.”

Chris Evans is equally clear on the long-term opportunity:

“These projects don’t just support renewables — they underpin the reliability of the entire future energy system.”

From the training pipeline to the delivery models, Harry Hartman believes the legacy will extend well beyond individual projects:

“What we build now in terms of skills and capability will define how successfully Australia can deliver complex underground infrastructure for generations.”

Success will depend on:

collaborative contracting models

realistic cost planning

integrating mining and civil methods

developing skills in underground and hydro-mechanical systems

major investment in workforce training

strong government support

early involvement of contractors, OEMs and community stakeholders

Pumped hydro will not be the only storage technology we rely on, but it is almost certain to be the backbone that keeps a high-renewable grid stable.

As more engineers, technicians, apprentices and delivery partners gain experience on these projects, they are not just building assets, they are shaping the next 80 years of Australia’s clean energy future.

Comments